The mold industry plays a crucial role in manufacturing, with molds being essential tools for shaping and producing a wide range of products. From automotive parts to household goods, molds are integral to modern production processes. As a result, the mold industry offers promising career opportunities for individuals interested in engineering, design, and manufacturing. In this blog post, we will delve into the intricacies of the mold industry, explore the various types, discuss the educational requirements, and outline the steps to building a successful career in this dynamic field.

Page Contents

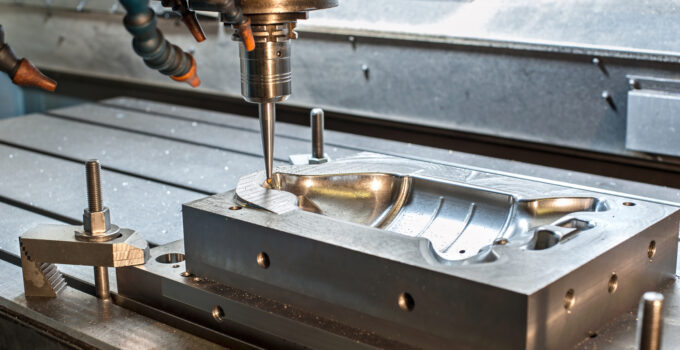

Understanding Molds: Types, Materials, and Applications

Source: wundermold.com

Molds come in various types, each serving a unique purpose. Injection molds, compression mustinesses, and blow mildew are some common examples. The choice of materials for decay-making is crucial, as it directly impacts the quality and durability of the final product. Metals, plastics, and composites are frequently used materials for fabrication. Understanding the applications of different mildew is essential, as it enables professionals to cater to diverse industries. Comprehensive knowledge of design and fabrication is essential to excel in this field.

Education and Training: Gaining Relevant Skills and Knowledge

Embarking on a career in the mold industry requires a strong educational foundation. Many colleges and technical institutes offer specialized courses in design, materials science, and manufacturing processes, providing a pathway to becoming a mold specialist. Pursuing degrees in engineering, industrial design, or materials science can also be advantageous, honing the skills needed for a successful career in decay making. Additionally, seeking certifications from renowned organizations can enhance the credibility and employability of aspiring specialists. Practical experience through internships and apprenticeships is invaluable, providing hands-on learning and exposure to real-world challenges, crucial for specialists to excel in their profession.

Getting Started: Finding Internships and Entry-Level Opportunities

Securing internships or entry-level positions is an excellent way to kickstart your decay career. Networking with enterprise professionals, attending job fairs, and exploring online job portals can lead to valuable opportunities. During internships, aspiring professionals can apply theoretical knowledge to real projects, hone their skills, and build professional connections. Entry-level positions offer a chance to work under experienced mentors, gaining insights into the industry’s best practices and refining their techniques.

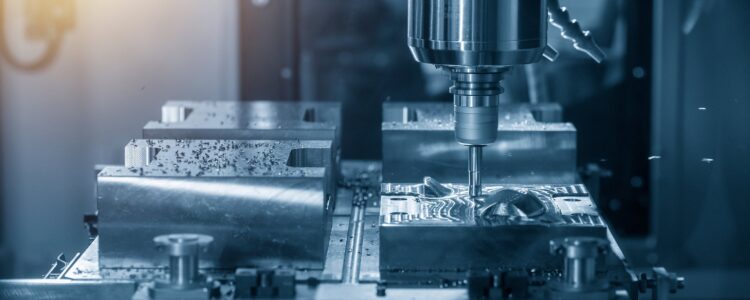

Advancing Your Career: Climbing the Mold Industry Ladder

Source: solidworks.com

Career progression in the mildew enterprise is achievable through dedication and continuous improvement. Seeking higher education, attending workshops and seminars, and staying updated on the latest technological advancements are essential steps. Developing leadership and management skills can lead to supervisory or managerial roles. Collaborating with cross-functional teams, taking on challenging projects, and showcasing innovation can set individuals on the path to success in this competitive field.

Work Environment and Safety in the Mold Industry

This industry often involves working with heavy machinery, hazardous materials, and complex processes. Consequently, ensuring a safe work environment is paramount. Employers must adhere to strict safety protocols and provide employees with proper training and protective gear. Additionally, cultivating a culture of safety awareness and reporting can prevent accidents and injuries, fostering a conducive working atmosphere.

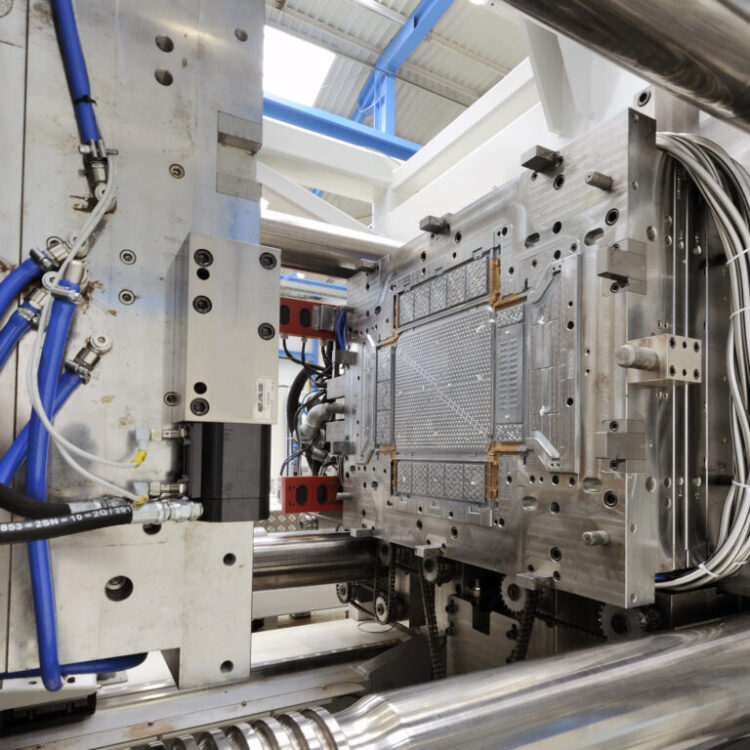

Embracing Technology: Automation and Digital Tools in Moldmaking

Source: easchangesystems.com

Embracing technology is a key aspect of modern mold making, with automation and digital tools revolutionizing the industry. Computer-Aided Design (CAD) software enables precise and intricate designs, reducing errors and accelerating the production process. Automation streamlines repetitive tasks, enhancing efficiency and reducing costs. Additive manufacturing, such as 3D printing, has expanded possibilities for complex geometries and rapid prototyping. Digital simulations optimize performance before actual production, minimizing risks. Embracing these technological advancements not only boosts productivity but also ensures mildew makers remain competitive in the fast-paced manufacturing landscape. Adaptation to these digital tools is essential for success and innovation in decay-making.

Despite the allure of the mold industry, professionals encounter challenges. These may include material limitations, design complexities, or market fluctuations. Problem-solving skills, adaptability, and collaboration are essential traits to overcome these obstacles. Staying informed about industry trends and best practices equips professionals to handle challenges proactively, ensuring sustained success.

Networking and Professional Associations in the Mold Industry

Source: jayconsystems.com

Networking and professional associations play a vital role in the mildew industry, fostering collaboration and knowledge-sharing among professionals. Attending industry events, conferences, and seminars provides opportunities to meet potential mentors, partners, and clients. Joining associations like the American Mold Builders Association (AMBA) or the Society of Plastics Engineers (SPE) offers access to a vast network of experienced individuals and valuable resources. These connections can lead to new business prospects, career advancements, and staying updated on industry trends. Engaging in networking and professional associations is a proactive step toward building a thriving career in the dynamic decay industry.

Sustainable Practices: Environmental Considerations in Mold Manufacturing

With growing environmental concerns, the mildew industry is gradually adopting sustainable practices. Using eco-friendly materials, recycling waste, and optimizing production processes can reduce the industry’s environmental impact. Embracing sustainability not only addresses societal expectations but also enhances the reputation of manufacturers in an environmentally conscious world.

Future Outlook: Exciting Trends and Opportunities in Mold-Making

Source: linkedin.com

The future outlook is filled with exciting trends and opportunities. Advancements in technology, such as additive manufacturing and smart molding, are revolutionizing the industry, making processes more efficient and cost-effective. 3D printing, in particular, is opening new possibilities for complex designs and rapid prototyping. The demand for sustainable practices is also driving innovation in materials and manufacturing techniques. Additionally, with the growing emphasis on customized and personalized products, makers can expect increased demand in various industries. Embracing these trends and staying updated on the latest developments will position professionals to thrive in the dynamic and promising future of mold-making.

Conclusion

In conclusion, the mold industry offers an exciting and rewarding career path for individuals with a passion for engineering, design, and manufacturing. By understanding different decay types, gaining relevant education and experience, embracing technology, and adopting sustainable practices, aspiring professionals can build successful and fulfilling careers in this thriving industry. Moreover, with constant innovation and future-oriented approaches, the mold industry is poised for growth, promising a bright future for those who embark on this journey.