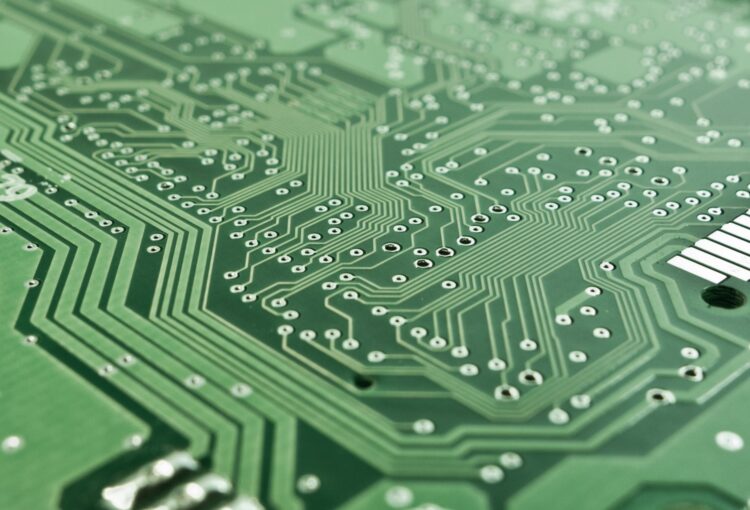

Copper clad laminate (CCL) sheets are an essential component in the manufacturing of printed circuit boards (PCBs). They play a crucial role in providing electrical conductivity, mechanical support, and insulation to the intricate network of electronic components on a PCB. In this article, we will delve into the basics of copper clad laminate sheets, exploring their composition, properties, and applications.

Page Contents

The Composition

Copper clad laminate sheets consist of multiple layers of materials bonded together. The core layer is typically made of a non-conductive substrate, such as fiberglass-reinforced epoxy resin. This substrate offers excellent mechanical strength and insulation properties, ensuring the stability of the PCB. On either side of the core layer, thin sheets of copper are bonded. The copper layers provide the necessary electrical conductivity for the circuitry.

The Properties

Electrical Conductivity

Source: newatlas.com

Copper is an excellent conductor of electricity, making it an ideal choice for PCBs. The copper layers in CCL sheets facilitate the flow of electrical signals between the various components on the board.

Thermal Conductivity

Copper also exhibits excellent thermal conductivity. This property helps in dissipating heat generated by the electronic components during operation, ensuring the reliability and longevity of the PCB.

Mechanical Strength

Source: jacoproducts.com

The fiberglass-reinforced epoxy resin core in CCL sheets provides exceptional mechanical strength. This allows the PCB to withstand the rigors of handling, assembly, and operation.

Insulation

The non-conductive substrate acts as an insulating layer, preventing short circuits between the copper traces on the PCB. It also protects against environmental factors such as moisture and contaminants.

Applications of CCL Sheets

Source: kllaminates.si

CCL sheets find applications in various industries where they are crucial for certain systems. Without them, they would not be able to function properly, or at all. Their applications include the following:

Electronics

PCBs made from CCL sheets are widely used in electronic devices such as computers, smartphones, televisions, and automotive electronics. They enable the interconnection of electronic components and ensure their reliable performance.

Aerospace and Defense

The aerospace and defense sectors rely heavily on PCBs for critical applications. Copper-clad laminate sheets provide the necessary electrical conductivity, thermal management, and durability required in these demanding environments.

Industrial Automation

Source: nsflow.com

CCL sheets are essential in industrial automation systems, including control panels, robotics, and machinery. They enable efficient signal transmission and power distribution in complex industrial setups.

Renewable Energy

With the growing emphasis on renewable energy sources, CCL sheets are vital in the manufacturing of solar panels, wind turbines, and energy storage systems. These sheets facilitate the efficient conversion, control, and distribution of electrical energy.

Summary

Copper clad laminate sheets are the backbone of modern electronics, serving as a crucial component in the production of PCBs. Their composition, combining a non-conductive substrate with copper layers, provides the necessary electrical conductivity, mechanical strength, and insulation properties. They find applications in diverse industries, including electronics, aerospace, defense, industrial automation, and renewable energy. As technology continues to advance, the demand for high-quality copper clad laminate sheets will undoubtedly grow, further driving innovation and development in the electronics industry.