Every building has wires connecting computers and other devices to wall jacks and outlets. More than that, there are unseen wires going every which way through walls, floors, and ceilings. These hidden wires are the life support of any communications network.

Working together with routers, modems, servers, and a host of other equipment, internal wiring ensures all these devices stay connected and are able to communicate for day-to-day activities. That being said, network slowdowns and even downtime can occur when these wires start having problems.

There are proper ways of wiring up a network, both in a practical sense as well as a legal one. Keeping up with these practices can make maintenance a breeze in the event something goes wrong. If errors do start cropping up, a network wiring test is the best way to locate and fix the problem, according to integratednetworkcable.com.

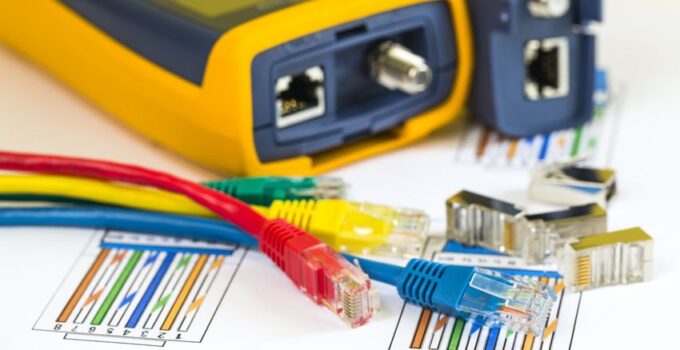

source:rs-online.com

Network wiring tests will start with a visual inspection of any accessible wiring. While some issues are easy to spot, such as a kink or other damage to a cable, others require a professional eye. This could include subtle damages along with being able to tell when installation was performed incorrectly and is not up to code.

These examinations will involve things such as checking wires for tangling, ensuring cabling has enough room for cooling, and ensuring cables are grounded to prevent electrical shocks. Many of these are small issues that have to do with organization and efficiency, but some problems could require correction to meet safety codes.

What Equipment is Needed to Perform a Network Wiring Test?

After the visual inspection has been performed, testing tools will be broken out to make more detailed examinations. Using these tools, an inspector will check to see that all cables are working at 100% functionality instead of merely working. Cables that give out completely are fairly obvious; someone will notice the connected devices have stopped working.

source:rs-online.com

But a damaged or older cable may not be performing at peak efficiency, which a network wiring test can pick up on. No tool lasts forever and cables are no exception. Time wears them down as do environmental hazards, from water damage to extreme temperatures to curious rodents looking for something to chew on.

The exact type of testing tool used will depend on what kind of cable is being examined, but most of these tools perform the same basic function. Signals are sent through the cable using the tester, which checks to see whether or not those signals make it from one end of the cable to the other correctly.

For example, a coax cable has a single copper line in the center of the cable. If that is worn out or damaged, the issues it causes will be fairly obvious. By contrast, an Ethernet cable uses eight smaller copper lines that work together to send a signal. If one of those eight conductors are damaged, the cable can still work but not as well as it should. Having one of those lines broken can even leave the cable functional, but severely underperforming.

How is Information from a Network Wiring Test Recorded?

source:gainexpress-dealer.com

After a professional has come out to perform the network wiring test, their company should compile the data and send over a detailed report. Typically, the raw data is there but also summarized into an easy-to-read format with bullet points detailing the results. Even if there is nothing wrong with a network and no room for improvement with network management, these reports are good to have on hand in case a problem does crop up sometime in the future.

But if any problems are found during the tests, the report will point those out. Glaring issues that need to be addressed to meet safety codes will be the most obvious while organizational issues may also be recommended to make the network run better. In either scenario, most companies that offer network wiring tests as a service should also be capable of implanting any of the solutions suggested. It may be tempting to do the bare minimum and only fix things that are broken now, but a little preventative maintenance now can also eliminate potential future issues.